Last week, I had an HP Laserjet P2015 with a serious attitude problem. The top two LED’s (Paper Jam and Toner) were stuck on. It is normal for the lights to illuminate after you first turn the printer on, but after a few seconds they should be replaced by just the ready light after the printer has finished its boot process. This one never finished booting. A few times the paper light would be the only one on. I know you don’t need pictures, but hey, I have them. The situation looked like this:

I kept trying to find the jam, opening covers and powering it on and off. Once I was done with the physical and verbal abuse, I noticed that the motor was running briefly after powering on, as it normally does during the startup process. The motor will NOT run if a jam is detected by the sensors (go ahead, stick a sheet of paper in a sensor and see!) This must mean the problem isn’t a jam right?

So what’s the deal?

Short answer: The formatter board.

Long answer: There is an IC on the board that uses a BGA form factor. As with many similar chips, especially early designs it seems, the failure is likely an open circuit due to a break in one of the solder balls from repeated thermal stress.

If it’s bad enough, the computer will not even recognize that there is a printer plugged in, though I’ve seen different combinations of the above symptoms.

So, you’re wondering how you can fix yours? Well, once you’ve determined that this is indeed your problem, the next step is pretty straight forward: you have to get to the formatter board. To do this, pull out the paper tray and toner cartridge. Then, firmly grasp the printers’ bottom left corner and pull back and outward to release it, repeating for the top left corner. It may help if you place the printer right side down on the desk and do it like this:

If a picture is worth a thousand words, that video should at least be worth a $1.50.

Once the side panel is off, you can see the formatter board. If you look down at it from the top side, you can even see the little balls of solder under the IC.

You’ll need to separate the board from the printer chassis. Start by unplugging the cables, carefully. Pull the ribbon cables with your fingers, griping them as close to the blue part as possible. Try not to bend them too much, as they are solid conductor. For the rest of the cables, just gently pull on the CONNECTOR to remove it from the socket, not the wires. If you pull on the wires, you risk pulling a wire out of the connector and complicating the project. You’ll want to remove the memory module too if you have one installed. Then, remove the four screws that hold the board in place.

You’re going to think this is a late April fool’s joke, but it’s actually not. The next step is to preheat your oven to about 350º Fahrenheit and remember, your printer doesn’t work now- so what do you have to lose?

To prep the board for baking, remove the white barcoded sticker from the middle of the board and the black sticker from the memory module slot. Those two stickers should be the only thing not capable of ‘taking the heat’.

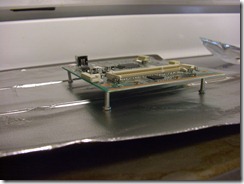

Next, you’ll want to get out a flat pan, like a cookie sheet. You’ll need to elevate the board above the pan so it doesn’t end up soldering itself to it. To do this, you could either carefully make four small tin foil balls to fit over the screw holes (make sure the foil does not touch anything soldered) or use my preferred method and find some larger diameter screws and jam ‘em into the mounting holes. You’ll want to position the board with the heavy components facing up, that is, the side with the memory slot, USB connector, and IC up.

Once the oven reaches the target temperature, place the whole thing in and monitor it. You’ll want to leave it in for about eight minutes.

What’s happening in the hot box? Well, if you haven’t figured it out yet, the heat is going to make all the solder on the board liquid, including (hopefully) the solder under that darn BGA chip. Once liquid, the open circuit should close and stay closed after it cools; the board will function normally again.

Once your eight minutes is up, turn off the oven and open the door to let it cool in place. It’s best not to move the board right now, since all the solder is in a liquid state. It only takes a small shift of one component and the whole board will be scrap. So, just let it sit there and cool in the oven until it reaches room temperature again.

After it has cooled, remove the temporary standoffs, replace the stickers, reinstall the board into the chassis, and carefully plug in the cables. Next, replace the toner and paper. Finally, plug in the printer, turn it on, and cross your fingers. This should happen:

If you get the above results, congratulations! Do a little happy dance. If yours still doesn’t work- you might have a bigger problem on your hands.

There is a alternate way of heating the board if you have the tools. I typically use a heat gun and a infrared thermometer to reflow my boards. This takes a little practice to hold the board at the target temperature and you have to get a feel for when you think it has reflowed. The end result is the same though.

Although this is a very common problem for this model, this printer isn’t alone. The problem exists on a few other similar HP printers and beyond that, many other devices. Just this week, I’ve reflowed two printers, an LCD, and a laptop.